SRM

Roller Mill

View More

What is non-metallic mineral grinding ring roller mill?

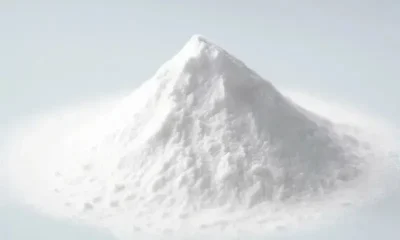

The non-metallic mineral grinding ring roller mill pulverizes non-metallic minerals into fine powder. It is designed and developed based on many years of research and experience in grinding mill production.

The ring roller mill has a unique design with a grinding ring and roller assembly. The grinding ring is fixed on the inner wall of the mill while the roller assembly rotates around the ring. As the roller assembly rotates, the material is fed into the mill and is ground between the grinding ring and rollers.

One of the advantages of the ring roller mill is its high grinding efficiency. The grinding ring and rollers are made of high-quality materials, which ensures a long service life and reduces maintenance costs. The unique design of the roller assembly also helps to increase the grinding efficiency by evenly distributing the material on the grinding ring.

Another advantage of the ring roller mill is its ability to grind various non-metallic minerals. It can be used to grind minerals such as limestone, calcite, marble, talc, barite, dolomite, etc. The mill can produce fine powder with a particle size range of 325-2500 mesh, suitable for various industrial applications.

In addition to its high grinding efficiency and versatility, the ring roller mill has a compact structure and small footprint. It can be easily installed and operated in small spaces, making it suitable for use in factories or production lines with limited space.

The ring roller mill also has a low energy consumption. The motor power is optimized to reduce energy consumption while maintaining the required grinding capacity. This not only helps to save energy costs but also reduces the environmental impact.

EPIC POWDER Makes World Better

20+ years of work experience in the ultrafine powder industry

Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder.

- Based on the development of the industry

- Deep cultivation of ultra-fine grinding

- Born for ultra-fine grinding and classification

- Easier handling of materials

Ring Roller Mill Display

Ring Roller Mill Working Principle

The ring roller mill uses the principles of impact, extrusion and grinding to crush materials. There are multiple layers of grinding rollers and grinding rings installed, and the material first falls between the uppermost grinding rollers and grinding rings. There is a large movable gap between the grinding roller installed on the grinding roller bracket and the pin shaft. When the material passes through the gap between the grinding roller and the grinding ring, the material will be crushed by the impact, extrusion and grinding of the grinding roller. When the material passes through the multi-layer grinding rollers and grinding rings from top to bottom, the material will be ground many times. Under the action of gravity, the crushed material falls to the bulk material tray at the bottom and is thrown to the airflow channel, and is brought into the classification area at the top by the airflow; the classifying wheel classifies the powder, and the qualified fine powder passes through the classifying wheel and enters the The dust collection system collects, and the coarse material is thrown to the inner wall of the diversion ring, and falls back into the crushing area for crushing.

Ring Roller Mill Features

- It can produce 325mesh-2500mesh product fineness at one time, from coarse powder to superfine powder, and the fineness of the finished product can reach D97≤5μm.

- At the same fineness, compared with ball mill, impact mill, jet mill and stirring mill, ring roller mill has higher production efficiency, lower energy consumption and lower production cost.

- At the same production capacity, compared with ball mill, impact mill, jet mill and stirring mill, ring roller mill requires less capital investment and shorter investment recovery period.

- Equipment installation is simple and fast, no multi-layer steel structure platform required, no large-scale civil works are required, and the equipment can be put into production after installation.

- Grinding rollers and grinding rings are made of high-hardness and wear-resistant materials, which have a long service life and ensure uninterrupted and reliable operation of the equipment.

- The entire set of equipment operates under negative pressure, and the efficiency of the dust collector is as high as 99.9%, ensuring no dust pollution during operation.

Ring Roller Mill Parameters

| Model | SRM800 | SRM1000 | SRM1250 | SRM1680 |

|---|---|---|---|---|

| Feed Size (mm) | < 10 - 20 | < 10 - 20 | < 10 - 20 | < 10 - 20 |

| Moisture (%) | < 5% | < 5% | < 5% | < 5% |

| Mill Motor (kw) | 75 | 132 | 185 | 315 |

| Classifier Motor (kw) | 15 - 18.5 | 22 - 30 | 37 - 60 | 55 - 92.5 |

| Fan Motor (kw) | 37 - 45 | 55 - 75 | 75 - 110 | 132 - 180 |

| Product Fineness (mesh) | 325 - 2500 | 325 - 2500 | 325 - 2000 | 325 - 1500 |

| Production Capacity (T) | 0. 5 - 4.0 | 1.0 - 8.0 | 2.0 - 12 | 3.0 - 20 |

Ring Roller Mill Application Case

Makes World Better

Finer Mterial For Better World

Our Latest Blog

Ring roller mill for for dry grinding of Calcium Carbonate

What is the difference between vertical mill and ring roller mill?

What is a Calcium Carbonate Vertical Roller Mill?

Unleashing the Potential of Ring Roller Mill: A Revolutionary Solution for Efficient Material Processing

How Kaolin Affect Mechanical Properties of Rubber