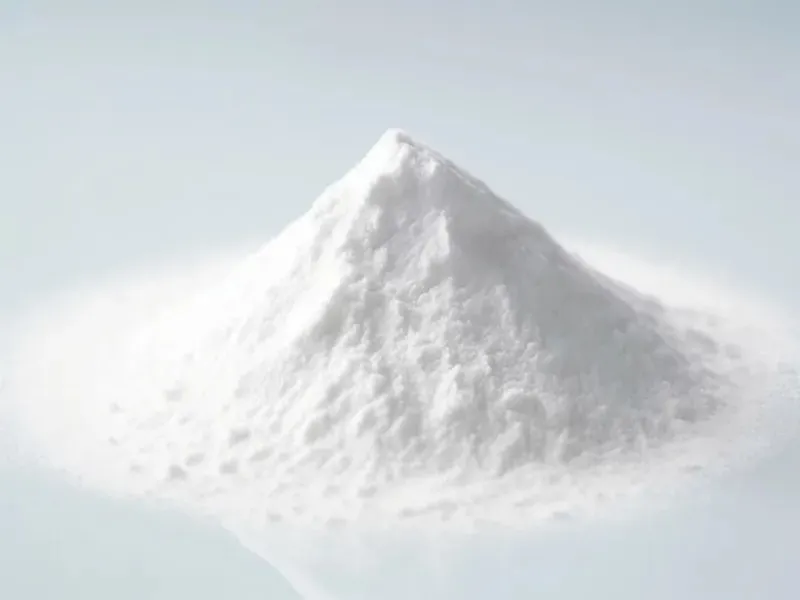

Un molino de rodillos anulares es ideal para moler carbonato de calcio en seco. Es eficiente y produce productos de alta calidad. A continuación, se ofrece una descripción general de su funcionamiento, beneficios y aplicaciones.

Descripción general de los molinos de rodillos anulares

Principio de funcionamiento

Molinos de rodillos anularesLos molinos de bolas y de anillos utilizan una combinación de fuerzas de impacto y de corte para moler materiales. Los componentes clave incluyen:

Anillo de molienda: Trayectoria circular donde se produce la molienda.

Rodillos: Se encuentran dentro del anillo. Ejercen presión sobre el material, reduciendo su tamaño.

El material se introduce en el molino, donde se tritura entre los rodillos y el anillo de molienda. La fuerza centrífuga mantiene el material en contacto con las superficies de molienda, lo que mejora la eficiencia de la molienda.

Ventajas

- Alta eficiencia: Los molinos de anillos permiten producir partículas más finas que los molinos de bolas tradicionales. Su diseño y funcionamiento lo permiten. Suelen producir polvos de carbonato de calcio. Sus tamaños de partícula varían de 5 a 45 micras.

- Ahorro de energía: Estos molinos consumen menos energía que otros métodos de molienda, por lo que son una opción rentable para la producción a gran escala.

- Versatilidad: Pueden moler cualquier dureza de carbonato de calcio, tanto grueso como fino.

- Mantenimiento reducido: Los molinos de rodillos anulares suelen tener índices de desgaste más bajos, lo que implica un menor mantenimiento.

Aplicaciones

Los molinos de rodillos anulares son comunes en las industrias que necesitan carbonato de calcio finamente molido. Lo utilizan para diversos fines.

Plásticos y pinturas: Se utilizan como rellenos para mejorar propiedades y reducir costos.

Productos farmacéuticos: para producir tamaños de partículas uniformes esenciales en la formulación de medicamentos.

Industria alimentaria: Se emplea en el procesamiento de alimentos como suplemento o estabilizador de calcio.

Comparación con otros molinos de molienda

| Característica | Molino de rodillos de anillo | Molino de bolas | Molino Raymond |

|---|---|---|---|

| Rango de tamaño de partículas | 5 – 45 micrones | 20 – 200 malla | Malla 80 – 600 |

| Eficiencia energética | Alto | Moderado | Moderado |

| Requisitos de mantenimiento | Bajo | Moderado | Moderado |

| Mecanismo de molienda | Impacto y cizallamiento | Impacto y desgaste | Compresión y molienda |

El molino de rodillos anulares es una excelente opción para la molienda en seco de carbonato de calcio. Tiene un excelente control del tamaño de las partículas y un bajo consumo de energía. Su uso en muchas industrias demuestra su versatilidad. Es eficaz para producir polvo de carbonato de calcio de alta calidad.